Re-think Efficiency – Time is money

Imagine an operation where there are no long days of standing at the lab bench and where analysts are freed up to learn new skills. Imagine receiving an email notification telling you samples in the lab are completed. Laboratory automation delivers all this and more. Re-think efficiency in your operation by exploring solutions that deliver 60% efficiency improvements and less than 2-year return-on-investment.

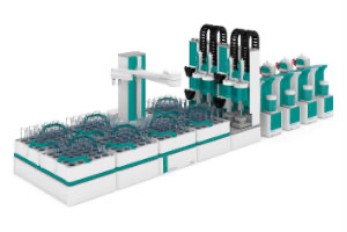

Four simultaneous analyses

Improving sample throughput and efficiency without adding staff is challenging. The OMNIS titration platform improves the modern analytical lab by making titration faster, safer and easier with automation that can analyze up to 4 samples simultaneously. Sample throughput is increased by 60% compared to existing laboratory automation solutions.

Automated sample preparation

Customized automation solutions have become a key part in increasing sample throughput as laboratories aim to maximize profitability. Many options are available that employ automated sample preparation techniques with ion chromatography. Labor required for filtration, calibration, and dilution of samples is virtually eliminated. Automated, precise, liquid handling eliminates human error while low cost-of-ownership allows laboratories to quickly achieve return on their investment.

Multiple results in seconds

In just a few seconds, one beam of light can give the same information as two or more analytical instruments. Combine common primary methods such as titration, chromatography, and even physical property analyses such as capillary viscometry into one 30 second scan. Near infrared spectrometers allow you to replace routine operation of single purpose instruments for faster measurements and more data.

Material identification without the lab

In the past, raw material identification took anywhere from hours to days to complete, with careful sampling protocols, paper riders, laboratory analysis, and review before a material could be cleared for release. With the handheld Raman technology, these measurements happen directly at the loading dock, which makes materials verification and release virtually instantaneous.

Real-time decision making

Process analysis boosts your efficiency by plugging your equipment directly into your process. This helps measure the most common chemical applications (hardness in brine, pH and caustic and soda) instantaneously! Unattended measurement supports real-time decision-making and avoids damaging components.

Corrosion control

Corrosion arguably increases costs and plant downtimes. To counteract corrosion effectively, a thorough understanding of the underlying corrosion processes and types are necessary. Electrochemical analyses such as linear polarization (LP) and electrochemical impedance spectroscopy (EIS) are ideal ways to investigate corrosion mechanisms, allowing you to characterize the processes and effects quickly and accurately.